Kodi Stacking Station Imagwira Ntchito Bwanji Makina Opangira Thermoforming

I. Chiyambi

M'malo opanga zinthu,makina a thermoforming zimagwira ntchito yofunika kwambiri popanga zida kukhala zinthu zenizeni. Pakati pazigawo zosiyanasiyana za makinawa, malo osungiramo zinthu mwakachetechete amagwira ntchito yofunika kwambiri, kuyang'anira njira zomaliza za ndondomeko ya thermoforming. Nkhaniyi ikufuna kupereka chidziwitso chatsatanetsatane cha malo osungira. Kugwira ntchito ngati gawo lofunikira pamzere wopanga ma thermoforming, malo osungiramo zinthu amathandizira kuti magwiridwe antchito azitha kugwira ntchito bwino, kuchepetsa ntchito, komanso kutsimikizika kwazinthu zapamwamba kwambiri. Lowani nafe pamene tikuwunika momwe masiteshoni amadumphira mkati mwake, ndikuwunika magawo awo, makina ake, zabwino zake, komanso momwe amakhudzira ukadaulo wa thermoforming.

II. Kumvetsetsa Makina Opangira Pulasitiki

Thermoforming process ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga mapepala apulasitiki kukhala zinthu zosiyanasiyana. Kuchita zimenezi kumaphatikizapo njira zingapo zofunika, kuyambira ndi kutentha kwa pepala lapulasitiki mpaka litatha. Pambuyo pake, pepala lofewa limapangidwa kuti likhale lopangidwa ndi nkhungu kapena mndandanda wa nkhungu. Fomu yofunidwa ikakwaniritsidwa, mankhwala apulasitiki amazizira ndi kulimba kuti asunge mawonekedwe ake. Kumvetsetsa kachitidwe kofunikira kameneka kumapereka maziko oti amvetsetse kufunikira kwa zigawo zomwe zili mkati mwa amakina odzaza ndi thermoforming . Izi ndi zigawo za makina thermoforming:

| Sitimayi | Tanthauzo |

| Kupanga Station | Malo opangira ndi gawo lofunikira pomwe pepala la pulasitiki lotenthedwa limasinthidwa kukhala mawonekedwe opangira. |

| Dulani Station | Pambuyo popanga siteji, pepala la pulasitiki lokhala ndi zinthu zopangidwira limasunthira kumalo odulira. |

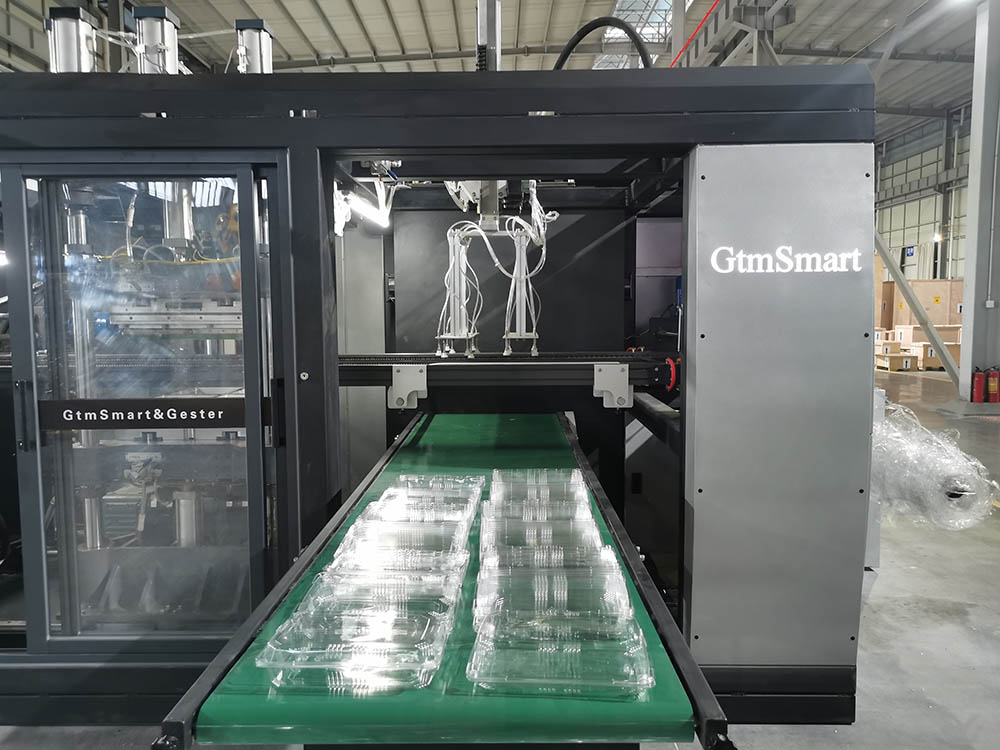

| Stacking Station | Malo osungiramo zinthu omwe amagwira ntchito ngati gawo lomaliza mu ndondomeko ya thermoforming. |

Kuzindikira magawo osiyanasiyanawa kumapereka chithunzithunzi chokwanira cha momwe makina opangira thermoforming amagwirira ntchito. Siteshoni iyi ya stacking imayang'anira kukonza bwino ndikusonkhanitsa zinthu zapulasitiki zowumbidwa, kuzikonzekeretsa kuti zitsatidwe ndi kugawa ndi kugawa.

III. Stacking Station: Zoyambira

Malo ojambulira mkati mwa makina opangira thermoforming ndi gawo lofunikira lomwe limapangidwa kuti lizitha kuyendetsa bwino kusinthaku kuchokera pamagawo opangira ndi odula mpaka gawo lomaliza. Cholinga chake chachikulu ndikusonkhanitsa mwadongosolo ndikupanga zinthu zapulasitiki, kuonetsetsa kuti ntchito ikuyenda bwino komanso kuwongolera njira zotsatila. Atayikidwa kunsi kwa malo odulirapo, amakhala ngati mkhalapakati pakati pa kupanga zinthu zapulasitiki payekha ndikukonzekera kuyika.

Ntchito zazikulu za Stacking Station:

1 . Kutoleredwa Kwa Zopangidwa:

Imodzi mwa ntchito zoyambira za stacking station ndikusonkhanitsa mwadongosolo zinthu zapulasitiki zomwe zangopangidwa kumene. Pamene zinthuzi zimachokera kumalo odulira, malo osungiramo zinthu amawasonkhanitsa bwino, kuteteza kusokonezeka kulikonse kwa mzere wopanga. Gawo loyambali ndilofunika kwambiri kuti pakhale ndondomeko yopangira zinthu mosalekeza komanso mwadongosolo.

2. Kusanjikiza Kwa Kugwira Ndi Kuyika Mosavuta:

Akasonkhanitsidwa, malo osungiramo zinthu amapita patsogolo pokonza zinthu zopangidwa mwadongosolo. Izi stacking osati facilities kunyamula mosavuta komanso optimizes gawo ma CD. Kukonzekera mwadongosolo kumatsimikizira kuti zinthuzo zimaperekedwa mofanana, ndikuwongolera njira zotsatiridwa ndi kugawa. Ntchitoyi imapangitsa kuti ntchito zonse zitheke bwino komanso zimachepetsa chiopsezo cha kuwonongeka panthawi yogwira ndi kuyendetsa.

IV. Ubwino Wogwiritsa Ntchito Stacking Station

Kuphatikiza ma stacking stations mupulasitiki thermoforming makina zimabweretsa zabwino zambiri, kuyambira pakuchita bwino komanso kuchepa kwa magwiridwe antchito mpaka kuwongolera kasamalidwe ndi kuyika kwazinthu, komanso njira zowongolera zowongolera. Zopindulitsa izi pamodzi zimathandizira kuti pakhale njira yolimbikitsira komanso yopikisana pakupanga pulasitiki.

1. Kuchulukitsidwa Mwachangu pa Zopanga:

Masiteshoni owunjika amathandizira kwambiri pakukulitsa magwiridwe antchito pamzere wopangiramakina a thermoforming . Pogwiritsa ntchito kusonkhanitsa ndi kukonza zinthu zopangidwa ndi pulasitiki, masiteshoniwa amachotsa zopinga zomwe zingachitike ngati njirayi itakhala yamanja. Kusanja mosalekeza komanso mwadongosolo kwazinthu kumapangitsa kuti ntchito ziziyenda bwino, kuchepetsa nthawi yopanda ntchito pakati pa magawo a thermoforming. Chifukwa chake, opanga amawona kuwonjezeka kwakukulu kwa magwiridwe antchito onse.

2. Kuchepetsa Zofunikira pa Ntchito:

Chimodzi mwazabwino zophatikizira ma stacking station ndikuchepetsa kofunikira kwa ntchito. Kudzipangira tokha kusonkhanitsa ndi kusungitsa njira kumachepetsa kufunika kochitapo kanthu pamanja pantchito izi zobwerezabwereza komanso zowononga nthawi. Izi sizingochepetsa ndalama zogwirira ntchito komanso zimalola ogwira ntchito kuti aziyang'ana kwambiri pazambiri zantchito yopangira, motero amakwaniritsa kugawa kwa anthu m'malo opangira.

3. Kasamalidwe ndi Kuyika Kwazinthu Bwino:

Masiteshoni owunjikira amathandizira kwambiri pakuwongolera ndi kulongedza kwa zinthu zopangidwa ndi thermoformed. Kuyika kwadongosolo kwazinthu kumatsimikizira kuwonetserako kofanana, kumapangitsa kuti zikhale zosavuta kutsata njira zotsika monga kuyika ndi kugawa. Kuwongolera kumeneku pakusamalira sikungowongolera magawo otsatirawa komanso kumathandizira kuchepetsa chiwopsezo cha kuwonongeka panthawi yamayendedwe. Kuwongolera kwapang'onopang'ono kwa kasamalidwe kazinthu kumawonjezera kusanja kwa magwiridwe antchito ndi magawo ogawa azinthu zopangira.

4. Kuwongolera Ubwino Wowonjezera:

Masiteshoni a stacking amakhala ngati poyang'ana kofunikira pakuwongolera khalidwe mkati mwa njira ya thermoforming. Kupyolera mu stacking zokha, malowa amatha kuphatikizira njira zowunikira kuti azindikire ndikulekanitsa zinthu zilizonse zolakwika. Izi zimakulitsa njira zowongolera zabwino zonse poletsa kuti zinthu zotsikirapo zisamapitirirebe pakupanga. Zotsatira zake, opanga amatha kukhalabe ndi khalidwe losasinthika lazinthu ndikukwaniritsa mfundo zokhwima zomwe msika umafuna.

V. Mapeto

Pomaliza, masiteshoni owunjika amakhala ngati magawo ofunikira mkati mwa njira ya thermoforming, gawo lawo lofunikira pakutolera, kukonza, ndikuwunika zinthu zomwe zidapangidwa zimatsimikizira kufunikira kwake pakuwonetsetsa kuti mzere wopangira bwino komanso mwadongosolo. Ubwino wofunikira wamasiteshoni osungiramo zinthu, kuphatikiza kuchuluka kwa kupanga, kuchepa kwa ntchito, kuwongolera bwino kwazinthu, komanso kuwongolera bwino, kumatsindika momwe amasinthira pakupanga pulasitiki. Kuyang'ana m'tsogolo, tsogolo laukadaulo wapa stacking station lili ndi zomwe zikuyenda bwino, ndikupita patsogolo kwa makina, matekinoloje anzeru, ndi njira zowunikira zabwino.

Nthawi yotumiza: Dec-14-2023