Maupangiri pa Kusankhidwa ndi Kugwiritsa Ntchito Makina Opangira Ma Thermoforming

I. Chiyambi

Tekinoloje ya Thermoforming ikukula kwambiri m'makampani amasiku ano opangira pulasitiki, ndikusankha ndikugwiritsa ntchito nkhungu kukhala chinthu chofunikira kwambiri pakuwonetsetsa kuti ntchito ikuyenda bwino. Nkhaniyi ikuyang'ana pazambiri za kusankha ndikugwiritsira ntchito makina a thermoforming, ndikukupatsani chiwongolero chokwanira. Kuchokera kusiyanitsa nkhungu zachitsulo zokhala ndi ma polima mpaka kusankha pakati pa dzenje limodzi ndi ziboliboli zambiri, timavumbulutsa zomwe zidapangitsa chisankho chilichonse.

II. Zambiri za Thermoforming Technology

M'malo opangidwa ndi pulasitiki, nkhungu zimatuluka ngati zigawo zofunika kwambiri, zomwe zimalongosola mizere yolondola ndi miyeso ya chinthu chomaliza. Nkhungu zimagwira ntchito ziwiri: kuthandizira kamangidwe kake ndikuwonetsetsa kuti zinthu zopangidwa zimafanana. Kaya amapangidwa kuchokera ku zitsulo kapena ma polima, nkhunguzi zimathandiza kwambiri kuti zikhale zabwino komanso zogwirizana ndi zinthu zopangidwa ndi thermoform. Ndimeyi ikuyang'ana kufunika kwa nkhungu popanga pulasitiki, kuyerekeza ubwino ndi ntchito za zitsulo ndi polima. Kuphatikiza apo, imayang'ananso zomwe zikukhudzidwa pakusankha pakati pa nkhungu zamtundu umodzi ndi ma cavity angapo, ndikuwunikira momwe zimakhudzira kupanga bwino komanso kutsika mtengo.

Mawonekedwe a thermoforming akusintha mosalekeza, kutengera kupita patsogolo kwaukadaulo komanso zofuna za msika. Mu gawoli, tikuwunika momwe zinthu ziliri zomwe zimapangidwira makampani opanga ma thermoforming ndi zomwe amafunikira. Kuchokera pakuphatikizika kwa matekinoloje a digito mpaka kuchulukirachulukira kwa machitidwe okonda zachilengedwe, kumvetsetsa zomwe zikuchitikazi ndikofunikira kuti mukhale odziwa zomwe zikuchitika mumakampani. Kuzindikira za zomwe zikuchitika komanso zomwe zikuyembekezeka mtsogolomu kumapereka chidziwitso chokwanira cha gawo la thermoforming, kuthandiza akatswiri kugwirizanitsa machitidwe awo ndi zofuna zomwe zikubwera.

III. Mitundu ya Thermoforming Machine Molds

A. Metal Molds vs. Polymer Molds:

Kusanthula Mofananiza Ubwino ndi Zoipa

Zitsulo zachitsulo ndi zoumba za polima zimayimira zisankho ziwiri zosiyana mu thermoforming, iliyonse ili ndi ubwino wake ndi zovuta zake. Zoumba zachitsulo, zomwe zimapangidwa kuchokera ku aluminiyamu kapena chitsulo, zimadzitamandira kulimba komanso kulondola, kuonetsetsa kuti zikugwiritsidwa ntchito kwa nthawi yayitali komanso kutulutsa kwapamwamba. Kumbali yakutsogolo, mtengo wawo wopanga ndi kulemera kwawo zitha kukhala zolepheretsa. Mosiyana ndi izi, nkhungu za polima, zomwe nthawi zambiri zimakhala ndi zinthu monga epoxy kapena ma resin ophatikizika, zimapereka zotsika mtengo komanso zopepuka. Komabe, amatha kuwonetsa moyo wautali komanso wolondola poyerekeza ndi anzawo achitsulo. Ndimeyi ikuyang'anitsitsa zabwino ndi zoipa zomwe zimagwirizanitsidwa ndi zitsulo ndi ma polima, zomwe zimathandiza opanga kupanga zisankho zodziwika bwino malinga ndi zofunikira zawo.

Mapulogalamu Oyenerera a Zida Zosiyanasiyana

Kuyenerera kwa nkhungu zachitsulo kapena za polima zimatengera momwe zimagwirira ntchito mkati mwa thermoforming process. Zitsulo zachitsulo zimawala muzochitika zomwe zimafuna tsatanetsatane wovuta, kulolerana kolimba, ndi kuwonjezereka kwapangidwe. Mosiyana ndi izi, nkhungu za polima zimapeza niche yawo m'mapulojekiti okhala ndi ma voliyumu ocheperako, zomwe zimapangitsa kuti pakhale kusamvana pakati pa kuwongolera mtengo ndi mtundu wovomerezeka. Poyang'ana mawonekedwe apadera komanso momwe angagwiritsire ntchito bwino nkhungu izi, gawoli limatsogolera opanga kuzisankho zoyenera zogwirizana ndi zolinga zawo zopangira.

B. Mabowo Amodzi-Cavity vs. Multi-Cavity Molds

Malingaliro a Kupanga Mwachangu ndi Mtengo

Chisankho pakati pa nkhungu zokhala ndi cavity imodzi ndi multi-cavity zimakhudza kwambiri momwe ntchito ya thermoforming ikuyendera komanso yotsika mtengo. Zoumba zapabowo limodzi, zomwe zimapanga chinthu chimodzi panthawi, zimapereka kuphweka komanso kuwongolera mosavuta koma zimatha kuchedwa pa liwiro la kupanga. Kumbali inayi, nkhungu zamitundu yambiri zimathandizira kupanga zinthu zingapo nthawi imodzi, kukulitsa mitengo yopangira koma kumafuna kukhazikitsidwa kovutirapo. Ndimeyi imafotokoza mwatsatanetsatane momwe ntchito yopangira imagwirira ntchito komanso mtengo wogwirizana ndi mitundu yonse ya nkhungu, kupatsa mphamvu opanga kupanga zisankho zoyenera zogwirizana ndi kukula kwawo ndi zomwe amafuna.

Kusankha Mtundu Woyenera wa Nkhungu

Kusankha pakati pa nkhungu za cavity imodzi ndi multi-cavity kumafuna kumvetsetsa kwapang'onopang'ono kwa zofunikira zopanga. Zinthu monga kuchuluka kwa madongosolo, liwiro lomwe mukufuna kupanga, ndi zinthu zomwe zilipo zimathandizira kwambiri popanga zisankho. Popereka zidziwitso pamalingaliro omwe akukhudzidwa, gawoli limathandiza opanga kusankha mtundu wa nkhungu womwe umagwirizana bwino ndi zolinga zawo zogwirira ntchito komanso zovuta zachuma.

IV. Mfundo zazikuluzikulu pakusankha Mold

Kusankha Zinthu ndi Kukhalitsa

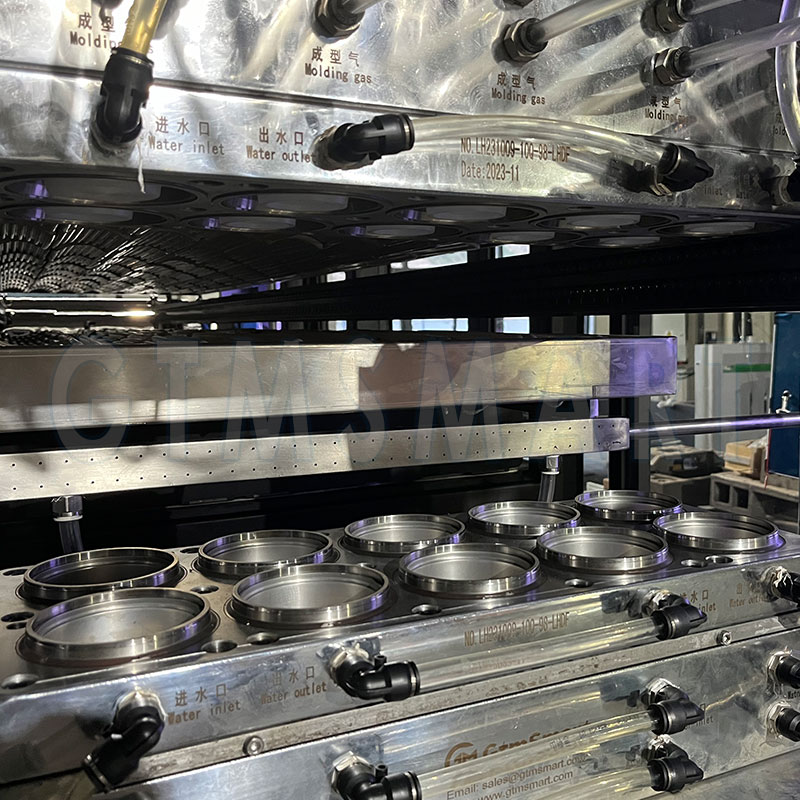

Kusankha zinthu zoyenera zopangira nkhungu ndizofunikira kwambiri pakuwonetsetsa kuti zizikhala ndi moyo wautali komanso magwiridwe antchito. M'nkhaniyi, kugwiritsa ntchito mbale za aluminiyamu 6061 ndizodziwika bwino chifukwa cha mawonekedwe ake odabwitsa. Mphamvu yachilengedwe komanso kukana kwa aloyiyi kumathandizira kukhazikika kwa nkhungu, kuwalola kupirira zovuta za njira za thermoforming. Kuphatikiza apo, kukana kwa dzimbiri kwa aluminiyamu ya alloy kumapangitsanso kulimba kwa nkhungu, kuzipangitsa kukhala zoyenera kugwiritsidwa ntchito kwanthawi yayitali komanso mwamphamvu.

Zofunikira Zopanga ndi Zolondola

Mapangidwe a nkhungu amatenga gawo lofunikira kwambiri pakukwaniritsa zomwe akufuna mu thermoforming. Mukasankha mbale za aluminiyamu za 6061, luso lawo lapadera limathandizira kupanga mapangidwe a nkhungu modabwitsa kwambiri. Kutha kukwaniritsa kulolerana kolimba komanso tsatanetsatane wovuta kumatsimikizira kuti nkhunguzo zimakwaniritsa zofunikira zomwe zimafunikira popanga zinthu zapulasitiki zapamwamba kwambiri. Ndimeyi ikuyang'ana mgwirizano wa symbiotic pakati pa mapangidwe a nkhungu ndi kulondola, kutsindika momwe 6061 alloy aluminiyamu imathandizira kukwaniritsidwa kwa makonzedwe ovuta komanso olondola.

Kusinthanitsa kwa Mtengo ndi Kupanga Mwachangu

Kulinganiza mtengo ndi mphamvu zopangira ndizofunikira kwambiri pakusankha nkhungu. Ngakhale mbale za aluminiyamu za 6061 zitha kuphatikizirapo ndalama zoyambira, kukwera mtengo kwawo pakapita nthawi yayitali kuyenera kuganiziridwa. Mtundu wopepuka wa aluminiyumu umachepetsa kulemera kwa nkhungu, zomwe zimapangitsa kuti pakhale mphamvu zopulumutsa mphamvu komanso kugwira ntchito bwino. Kuphatikiza apo, kumasuka kwa machining aluminiyamu kumathandizira kuti pakhale njira zopangira mwachangu, zomwe zimapangitsa kuti pakhale zotsika mtengo. Gawoli limasiyanitsa zamalonda pakati pa ndalama ndi kupanga bwino, ndikupereka chidziwitso cha momwe kusankha kwa nkhungu, makamaka 6061 alloy aluminium, kungakhudzire chuma cha ntchito za thermoforming.

V. Zochita ndi Kugawana Zomwe Zachitika

M'malo a thermoforming, GtmSmartMakina Opangira Ma Cup Otayika imayima ngati phunziro lodziwika bwino, makamaka pakusankha kwake zida za nkhungu. Zomwe zimagwiritsidwa ntchito makamaka zimagwiritsa ntchito mbale za 6061 alloy aluminium. Kusankha mwadala kumeneku kumayendetsedwa ndi chikhumbo chofuna kugwiritsa ntchito zabwino zomwe zimaperekedwa ndi aloyi ya aluminiyamu m'malo opangira makapu otaya.

Kusanthula Mawonekedwe Odziwika

Kugwiritsa ntchito mbale 6061 aloyi aluminiyamu mupulasitiki chikho thermoforming makinamphesa zimapanga zinthu zingapo zochititsa chidwi:

1. Kukhalitsa ndi Moyo Wautali: Mphamvu yachilengedwe ya 6061 alloy aluminium imatsimikizira kukhazikika kwa nkhungu, kuwalola kupirira kutenthedwa mobwerezabwereza ndikupanga mizunguliro yokhudzana ndi kupanga kwamphamvu kwa makapu otaya. Kukaniza kuvala ndi kung'ambika kumathandizira kuti nkhungu ikhale ndi moyo wautali komanso kusasinthika kwazinthu.

2. Kulondola Pamapangidwe A Cup: Kuthekera kwapadera kwa aluminiyumu ya 6061 alloy kumathandizira kupanga nkhungu zokhala ndi mapangidwe odabwitsa komanso mwatsatanetsatane. Kulondola kumeneku ndikofunikira kwambiri pakukwaniritsa makapu opangidwa, kukwaniritsa miyezo yapamwamba yomwe ikuyembekezeka pamsika wamakapu otayidwa.

3. Kupanga Kopanda Mtengo: Ngakhale kuti ndalama zoyamba mu mbale za aluminiyamu za 6061 zitha kukhala zapamwamba, kukwera mtengo kwanthawi yayitali kumawonekera. Mtundu wopepuka wa aluminiyumu umachepetsa kulemera kwa nkhungu, zomwe zimapangitsa kuti pakhale mphamvu zopulumutsa mphamvu komanso kugwira ntchito bwino. Kumasuka kwa makina a aluminiyamu kumathandiziranso kupanga njira zofulumira, kukhathamiritsa kukwera mtengo kwa Smart Disposable Cup Forming Machine.

Kafukufukuyu akuwonetsa momwe kusankha mwanzeru zinthu za nkhungu, monga aluminiyamu ya 6061 alloy, kungakhudzire kwambiri magwiridwe antchito, kulimba, komanso kutsika mtengo kwa njira za thermoforming pamapulogalamu adziko lenileni.

Mapeto

Pomaliza, kuwunika kwathunthu kwaukadaulo wa thermoforming, mitundu ya nkhungu, ndi zofunikira pakusankha nkhungu zimatsimikizira kusakanikirana kwazinthu zomwe zimapanga mawonekedwe opanga pulasitiki. Kugwiritsiridwa ntchito kwa mbale za aluminiyamu 6061 monga chinthu chachikulu cha nkhungu kumawoneka ngati chisankho chanzeru, chopatsa mphamvu pakati pa kulimba, kulondola, ndi kutsika mtengo. Nkhani yophunzira ya GtmSmartmakina opangira makapu apulasitikizikuwonetseratu zofunikira za kusankha kwazinthuzi, kusonyeza momwe zimathandizira kuti makinawo azigwira ntchito bwino, kukhala ndi moyo wautali, komanso kupanga makapu apamwamba omwe amatha kutaya.

Nthawi yotumiza: Dec-18-2023